Well I am playing things as safe as I can these days but when a client calls with no heat I can’t just ignore it. This guy’s thermostat broke, he called a plumber, and the plumber confirmed that the thermostat was broken and charged him $85. yeesh.

So the client decided to go upscale with a new NEST thermostat. It was a bit of a hassle picking it up at Home Depot as they keep them locked up (at $250 a pop I can see why). And I was unsure about the compatibility with his system so I made some phone calls, and Google, which now owns Nest, said I was good to go.

So in we start Here’s the box:

So I pulled off the old thermostat,

More on the hole later, for now I had to get the furnace going, so,

Two rules for installing a therm: 1) turn off the furnace first and 2) Do NOT let the wires slip back down the wall.

yikes, there was a major hole in wall. blue tape used here to support wires:

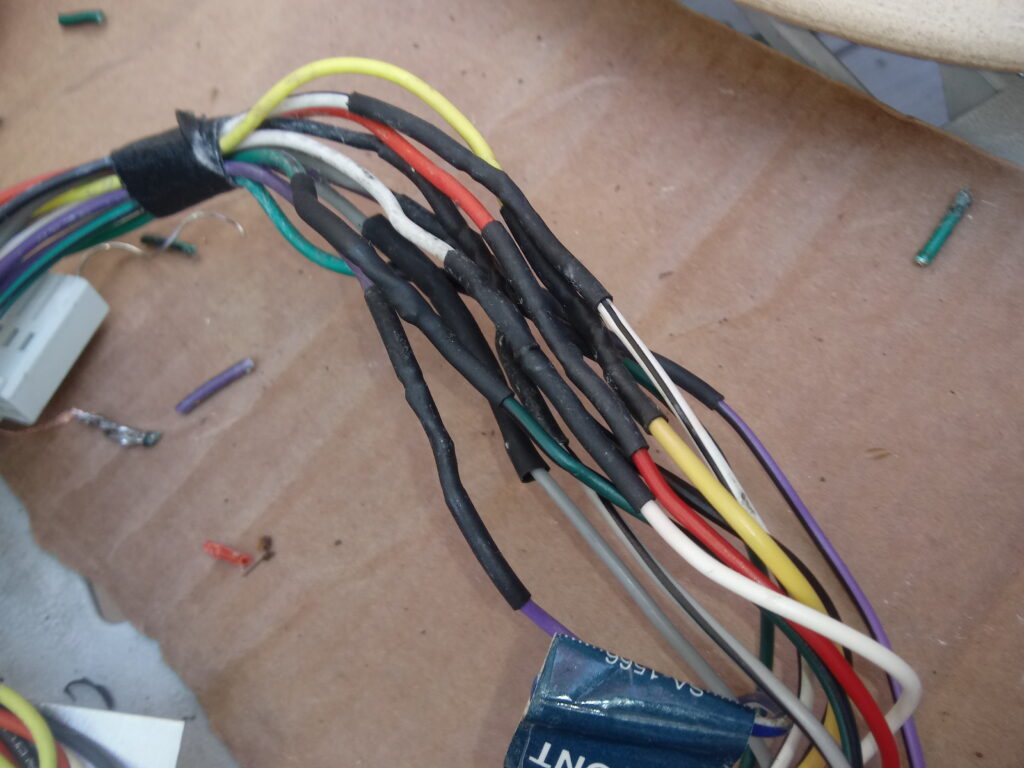

(Note what I assume were low voltage door bell wires spliced in there, I taped them up and moved on to bigger things)

(Note what I assume were low voltage door bell wires spliced in there, I taped them up and moved on to bigger things)

And then there is an APP to use in installing the thing. Now here is the big deal, I was always told that to install a smart thermostat you need a COMMON WIRE to allow it to charge. This house only had two wires to turn the furnace on and off, but, Google/Nest repeatedly said I do NOT need a common wire, so, off we go. In this case just simple RH (red/heat) and White (neutral) wire:

(note, in the pic, R and W wires not hooked up yet)

At this point I was assuming I would have to come back and patch this godawful hole in the wall but then I discovered that Google in its infinite wisdom provides a massive faceplate, so I put that on and it was big enough to cover the hole, and

VIOLA

At this point I thought I was done but then . . . but then . . . the client and I spent 90 minutes on the phone to google help, which, I have to say, was fantastic. The setting up of the “APP” on the guy’s phone and making the thing talk to his wifi and setting up the on off program was nightmarish BUT . . . WE DID IT.