It seems like every week someone calls me to solve a problem that no one else has been able to figure out. This time, a client had someone install a dishwasher, but they didn’t do it right.

You can’t see it in the above, but various things were wrong here. The dishwasher was listing to starboard, but more importantly, the “mounting tabs” that keep the thing from tipping over into the kitchen were not installed.

You can’t see it in the above, but various things were wrong here. The dishwasher was listing to starboard, but more importantly, the “mounting tabs” that keep the thing from tipping over into the kitchen were not installed.

The reason for this was, the flooring of the kitchen was higher than the untiled subflooring under the dishwasher, so when it was shoved into the space, it dropped about half an inch.

This made for a really ugly look of course, but also, the gap made it almost impossible to connect the mounting tabs. And, sadly, the installer skipped town WITH the tabs, so we had to get new.

Well guess what. No one has them. Not Amana, not Home Depot, nobody. Finally I found an appliance parts place in Needham that had them.

So it took 3 of us to manhandle the thing out of the enclosure because of the drop in the floor . . .

Bear in mind, I don’t install dishwashers, that’s way too much new plumbing and electrical. Anyway, I bought some slats of 1/4″ thick wood at Home Depot, and cut them to fit, to make runners that were level/flush with the kitchen floor. Then I used the dishwasher’s “leveler feet” to set the ideal height for the opening, slid it in, and connected the mounting tabs.

Looks and seems pretty simple now, but troubleshooting this and coming up with workarounds for that floor height problem took some serious synaptic activity!!! All in day’s work . . .

Looks and seems pretty simple now, but troubleshooting this and coming up with workarounds for that floor height problem took some serious synaptic activity!!! All in day’s work . . .

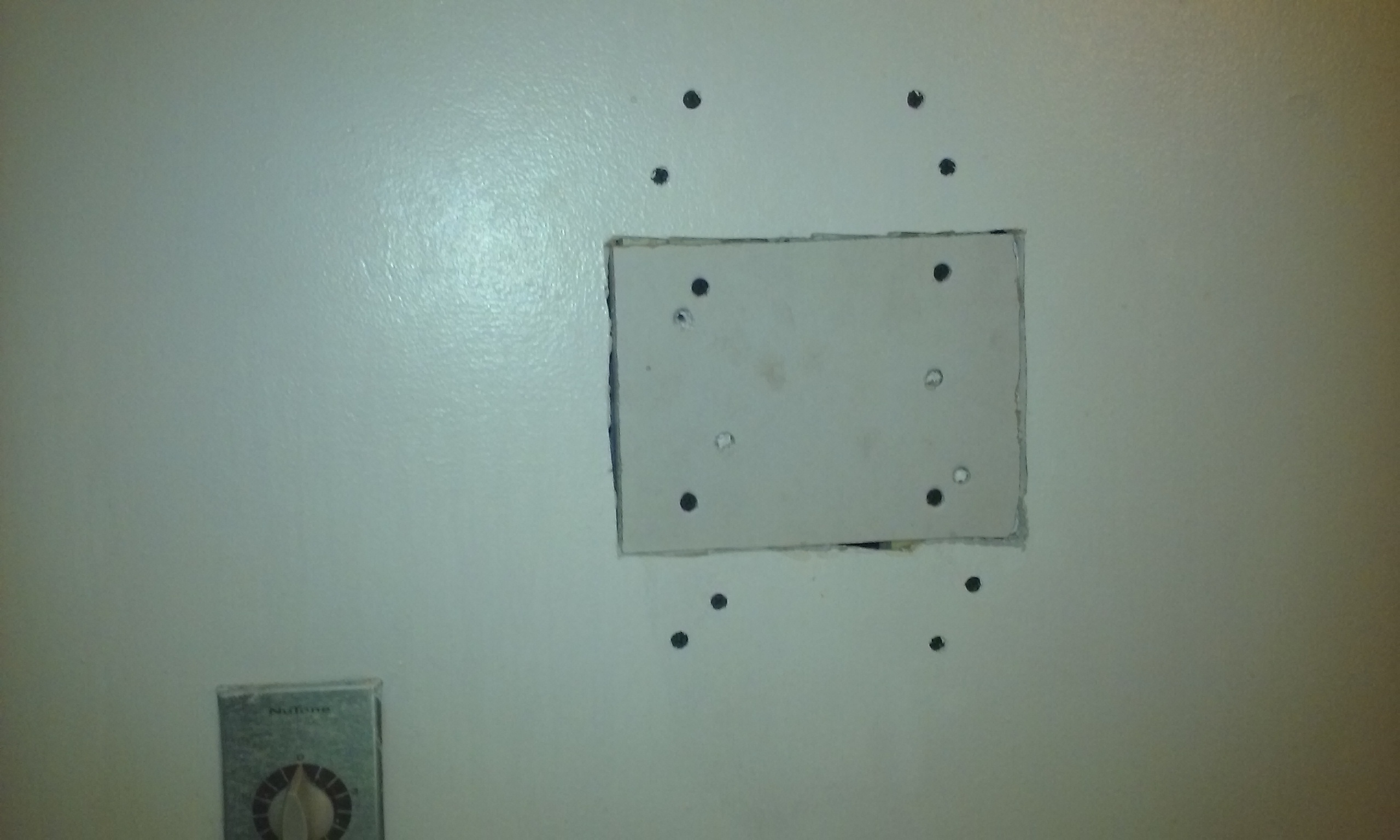

Obviously it needs a final coat of paint but it’s all sanded and primed and ready to go.

Obviously it needs a final coat of paint but it’s all sanded and primed and ready to go.